stone coated roofing tile production line China

Basic Info

Model No.: ZT-009

Product Description

stone coated roofing tile production line China

The stone coated roofing tile production line is to produce the stone coated roofing tile. these kind of tile is much mores strong and beautiful then other type roofing sheet. Our factory is professional make the stone coated roofing tile production line China.The stone coated roofing tile production line China is included below parts:

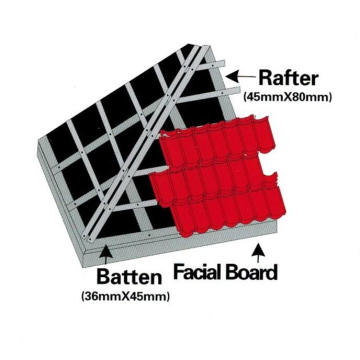

1 One machine with Leveling ,device Hydraulic Cutting device ,Slitting device (2) Description: (1 ) Coated metal roof tile is a modern environmentally friendly roofing material with the basic of 0.4mm Al-zin coated steel. Covering color vermiculite surface which carried under the high temperature technology. It is high-performance, stable, energy-efficient and easy operation. (3) This stone-coated roof tile machine line is included below parts: stone coated line Plate slitting shearing machine flower shearing machine Hydraulic press machine roof tile mold bending machine Punch-200 T--450T (4) Profile sizes: (1) Profile drawing and requirements: Aluzinc 1350 mm X 420 mm X 0,4 mm (2) Machine picture for your reference (5) Stone coated roofing sheet forming flow: 1. Material 1.1 Coil material:color Sheet, galvanized sheet 1.2 Coil material thickness: 0.4mm- 0.7mm 1.3Feeding width:1250mm 2. Formed stone coated line Step 1: The base roofing tile profile forming 5 Ton manual decoiler -One machine with Leveling ,device Hydraulic Cutting device ,Slitting device -Trimming machine -Punching machine 1 5 Ton decoiler Price: USD 500 Hydraulic Uncoiler Coil inner diameter 450-550 mm Max coil out diameter 1300 -1600 mm Max coil width 1250 mm Carrying capacity 5 T 2 Beveling Cut and slitting machine The price is: 9800USD 1.1 Shaft material: 45# steel, outer diameter 80mm 1.2 Number of shaft:1 step of feeding, up: 2 pieces, down:2 pieces 1.3Gear transport 1.4Forming speed:15m/min 1.5Main motor power:3kw 5. Trimming machine The price is: 1600USD Material mold: D2/GCr12MoVo Power: 3 kw Price of the machine and cut mold: This mold is equal to two molds which can work with the two sides

2 Trimming machine

3 200 Ton press machine

4 mold

5 the stone coated machine line

5. Punching machine

200 Ton press machine 315 Ton press machine

The price is : 19200USD The price is : 24600USD

stone coated roofing tile production line

Stone Coated Metal Roofing Systems

Stone Coated Tile Production Line China manufacturer

Color Stone Chip Coated Metal Roof Tile Forming Machine

Step Tiles Aluminium Roofing Sheet

Classic Roof Tiles

Onduvilla Roofing Tiles

Tilcor Royal Roof Tile

Onduvilla Roofing Tiles

Metro Classic Roof Tile

Metro Roman Roof Tiles

It is including five main parts:

1 Auto bottom glue spraying section

2 Auto stone coated section

3 The first time drying section

4 Auto face glue spraying section

5 The second time drying section

NO. 1 Auto bottom glue spraying section

Appearance size 4000*1000*2000mm

Driving section 3KW Excitation motor or frequency speed regulation (AS per customers` requirements )

Automatic pressure spray tank 1 set ; Capability: 200kg ; Range: 0.6~1Mpa

Automatic glue machine motor Servo motor ; Power: 750w ; PLC

Automatic spray gun 4 set (spare parts)

Dust collecting fan 1 set ; Power: 200w

Damp proof lamp 1 pc ; Power: 100w

Conveying device Chain reciprocating

Air Compressor 1 set ; Power: 7.5kw

Dust control of axial flow fan 1 set ; Power: 200w

Agitator 1 set ; Power: 1.5kw

NO. 2 Auto stone coated section

Appearance size 3500*1000*1500mm

Framework Steel welding

Conveying device Chain reciprocating

Automatic sand hopper 1 set ; Capability: 200kg

Bucket lift 1 set

Manual sandblast gun 4 sets

NO. 3 The first time drying section

Appearance size 25000*1000*1200mm

Framework Steel welding

Frame type thermal insulation wall 1.2mm cold steel with Rock wool

Automatic temperature controller 4 sets ; Range: 0°~160°

Infrared heating tube 30pcs ; Power: 30kw

Conveying device Chain reciprocating

Air cooling device 1 set ; Power: 200 w

NO. 4 Auto face glue spraying section

Appearance size 3000*1000*2000mm

Framework Steel welding

Damp proof lamp 1 pc ; Power:100w

Automatic pressure spray tank 1 set ; Capability: 200kg ; Range: 0.6~1Mpa

Conveying device Chain reciprocating

Automatic spray gun 4 sets (spare parts)

Manual patch glue gun 4 sets

Dust control of axial flow fan 1 set ; Power: 200w

Automatic glue machine motor Servo motor ; Power: 750w

NO. 5 The second time drying section

Appearance size 30000*1000*1200mm

Framework Steel welding

Frame type thermal insulation wall 1.2mm cold steel with Rock wool

Automatic temperature controller 4 sets ; Range: 0°~160°

Infrared heating tube 30pcs ; Power: 30kw

Conveying device Chain reciprocating

Air cooling device 1 set ; Power: 200 w

Contact us if you need more details on Stone Coated Roofing Tile Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Stone Coated Roofing Tile Production Line、Stone Coated Roofing Tile Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine